Explosion proof-flameproof intrinsically safe fingerprint-based door access control system

Flameproof intrinsically safe fingerprint-based door access control system, covering various aspects including technology features, safety compliance, applications, and maintenance requirements

🢖 About the System

🢖 System Features

🢖 Benefits of the System

🢖 Case Studies

🢖 Regulatory Compliance

🢖 Applications

🢖 Technology and Innovation

🢖 Installation and Maintenance

Oil and gas pipeline automation and instrumentation

Oil and gas pipeline automation and instrumentation, covering various aspects including technology solutions, safety measures, regulatory compliance, and support services

🢖 About Pipeline Automation and Instrumentation

🢖 Benefits of Automation and Instrumentation

🢖 Case Studies

🢖 Regulatory Compliance

🢖 Safety and Environmental Considerations

🢖 Technology and Innovation

🢖 Training and Support

Meters: Major supplier of meters with technology, Positive Displacement type, Coriolis, Mass, Thermal, Vortex, Acoustic (SAW)

Flow meters for steam, water, oil, air, and gas, covering various aspects including technology overview, applications, benefits, installation, maintenance, and support

🢖 About Flow Meters

🢖 Flow Meter Types

🢖 Technology Comparison

🢖 Applications

🢖 Benefits of Using Flow Meters

🢖 Case Studies

🢖 Installation and Calibration

🢖 Maintenance and Support

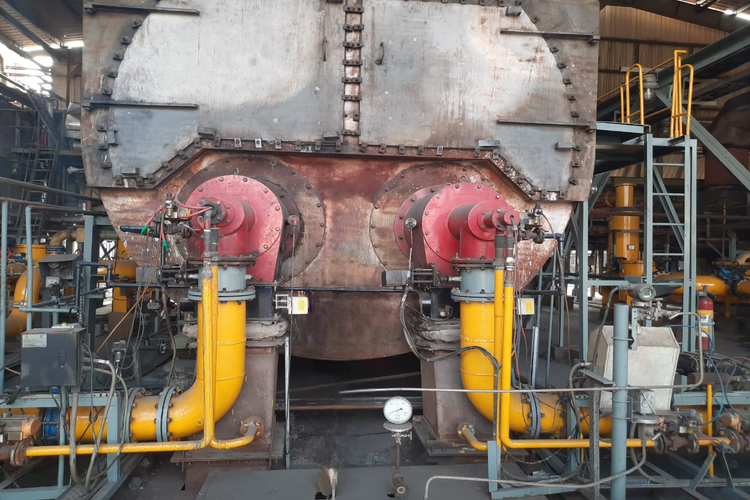

Burner retrofit and energy optimization with decarbonisation for all kind of Heaters/Boilers

Burner retrofit and energy optimization with decarbonisation, covering various aspects including technology solutions, benefits, regulatory compliance, industry applications, and support services

🢖 About Burner Retrofit

🢖 Burner Retrofit Services

🢖 Benefits of Burner Retrofit

🢖 Decarbonisation Strategies

🢖 Case Studies

🢖 Regulatory Compliance

🢖 Technology and Innovation

🢖 Industry Applications

🢖 Training and Support

For Dairy, we have good pilot case of Digitalization of Workflow of Dairy Ecosystem on Internet CLOUD based Technology

We are building Milk procurement System with Saas software modules to compile all relevant information and transfer on cloud through Online Application for registration of new milk pouring members. Easy Integration with the available milk analyzer and digital weighing scale at various DSC, BMC and members through and linked to AADHAAR database through PoS device and CLOUD login

Fuel conversion Consultancy, Technology and product supply: coal to biomass and biomass to coal retrofit

Solid fuel coal to biomass and biomass to coal retrofit solutions, covering various aspects including technology solutions, benefits, regulatory compliance, industry applications, and support services

🢖 About Retrofit Solutions

🢖 Coal to Biomass Retrofit

🢖 Biomass to Coal Retrofit

🢖 Benefits of Retrofitting

🢖 Case Studies

🢖 Regulatory Compliance

🢖 Technology and Innovation

🢖 Industry Applications

🢖 Training and Support